We are working for a sustainable future with our SPP project on 90 decares of land in Nevşehir Kozaklı district.

AC Power: 5,000 kWe | DC Power: 6,263 kWp, we prevented 4640 tons of CO2 emissions, saved 693 trees and produced electricity equivalent to the electricity needs of 1942 households.

We are at ANKIROS 2024!

Between September 19 - 21, we, as FAF Döküm Sanayi, took our place at the Ankiros Fair.

We are at CastForge 2024!

As FAF Döküm, we took our place in the CastForge 2024 fair held in Stuttgart, Germany between June 04-06, 2024 and shared our experiences with all valuable visitors who will participate.

Laboratory

We are not satisfied with our production and control systems in accordance with ISO 9001 VE (Pressure Vessels Bulk) standards, we have adopted the principle of continuously developing perfectionist production. In this regard, we strive for the highest quality production with our experienced staff as well as our metallurgical and sand laboratories and our wide range of measuring instruments.

Completion

It is the process of removing unwanted layers on the cast parts by means of metal particles thrown at high speed.

Melting

Our company has 2 units 2000 kg. capacity double pot dual trak, 2 units 1000 kg. capacity double pot dual trak inductotherm brand furnaces. The furnaces melt in 45 min. and have an automatic weighing system. Up to 6500 kg. single piece casting can be made.

Molding

Molding shapes and details available in our company

Modeling

It is the acceptance process we carry out with our 7 laboratory devices and various measuring instruments in order to select the qualified raw material we need to make the highest quality production.

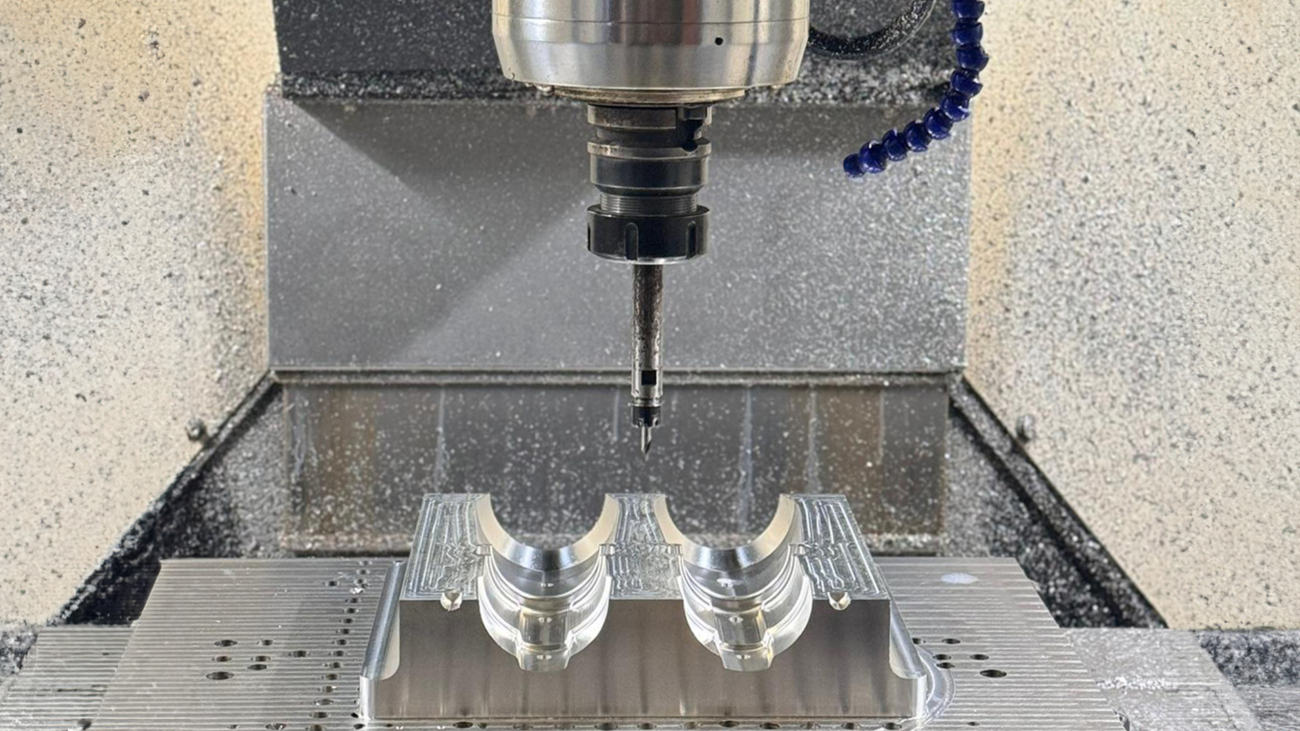

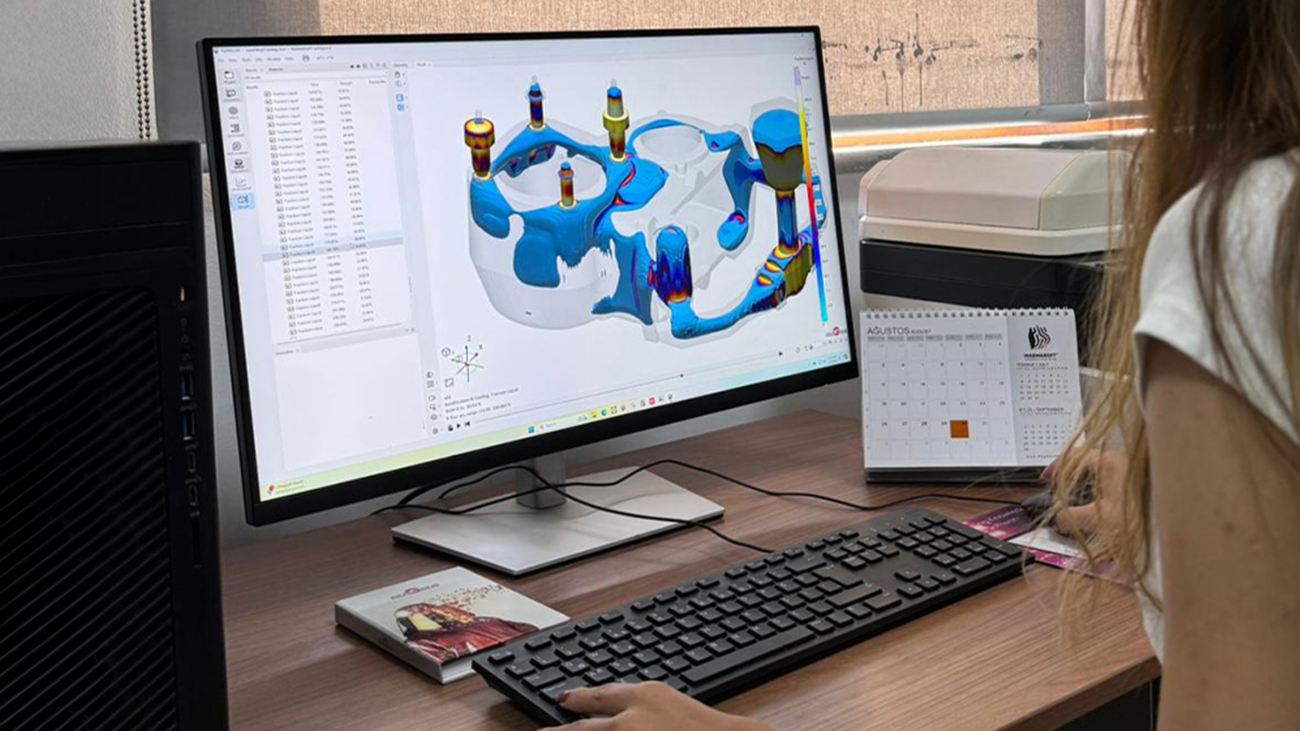

Method and Simulation

With the SOLIDWORKS program used in the production planning and R&D department, a 3D drawing of the part to be produced is made.